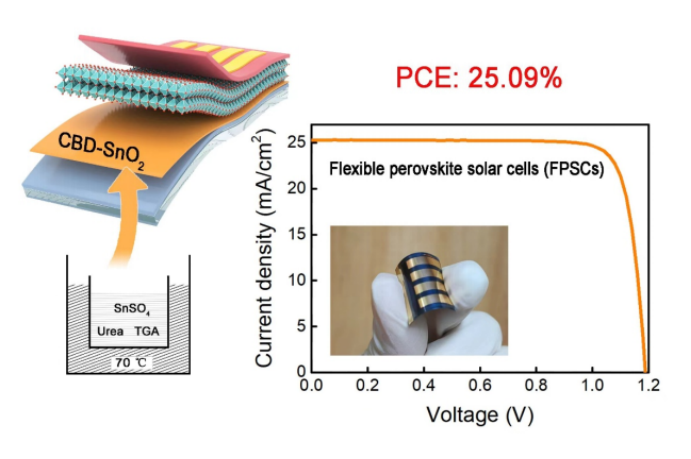

By developing a chemical bath deposition process for stannum dioxide (SnO2) electron transport layers suitable for flexible substrates, the team achieved a world-record efficiency of 25.09% (certified efficiency of 24.90%) for flexible perovskite solar cells.

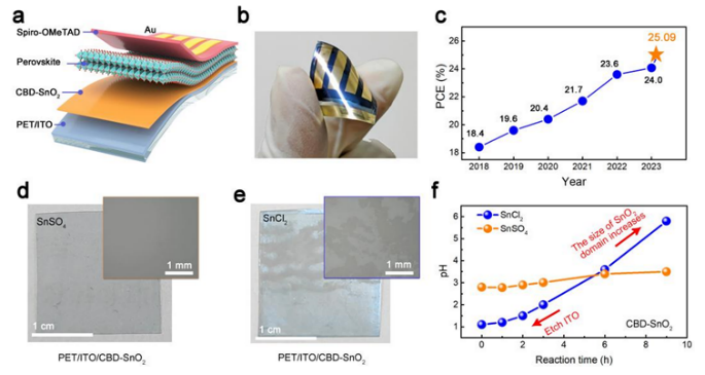

Flexible perovskite solar cells (FPSCs) have attracted significant attention due to their unique advantages such as lightweight, high power-to-weight ratio, and flexibility. However, both the processing and usage of FPSCs can be affected by external forces and deformation. Moreover, flexible substrates commonly used, such as PET, are difficult to withstand temperatures exceeding 150°C for extended periods. Therefore, it is challenging to deposit conductive films like FTO, which require high-temperature post-treatment, on the surface. Consequently, materials like ITO are used instead. However, ITO is susceptible to corrosion by strong acids under low pH conditions, making it difficult to prepare high-quality SnO2 electron transport layer films on such flexible substrates using the traditional chemical bath deposition method with SnCl2 and hydrochloric acid (with a minimum pH of approximately 1). Consequently, the efficiency of FPSCs still significantly lags behind that of rigid devices.

Diagram and physical representation of flexible devices, along with efficiency testing curves of FPSCs prepared based on chemical bath deposition

To address these challenges, the team at Tsinghua University developed a novel process for preparing high-quality SnO2 electron transport layers. By using SnSO4 instead of conventional SnCl2 as the stannum source, SnO2 films could be grown controllably under constant pH conditions without the need for strong acids, making them suitable for acid-sensitive flexible ITO substrates. This mild and controllable growth environment resulted in uniformly covered dense SnO2 films, leading to FPSCs with an efficiency of 25.09% (certified efficiency of 24.90%), setting a new world record for FPSCs.

Progress in the highest efficiency of FPSCs and the differences in preparing SnO2 films on flexible substrates using SnCl2 and SnSO4

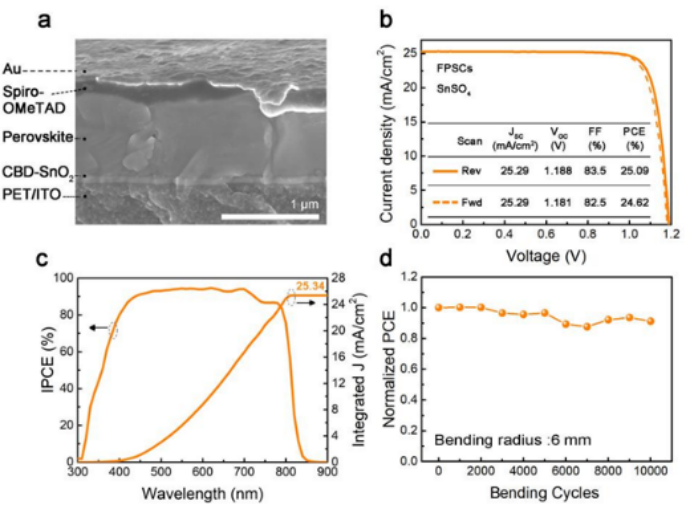

SEM image and performance test results of FPSCs

FPSCs based on SnSO4 exhibited excellent durability, maintaining over 90% of their initial photovoltaic conversion efficiency after 10,000 bending cycles. Tests also showed that SnO2-based electron transport layers prepared using SnSO4 (compared to SnCl2) demonstrated better thermal stability. This can be attributed to the strong interaction between SO42- on stannum sulfate-based SnO2 and Pb2+ ions, which reduces interface defects and enhances the thermal stability of perovskite devices. Additionally, the controllable growth of SnO2 in the new process ensures excellent reproducibility of the chemical bath process and enables the reuse of the chemical bath, saving raw materials and reducing environmental impact.

The related research results, titled “25%-Efficiency Flexible Perovskite Solar Cells Via Controllable Growth of SnO2”, were published on March 22, 2024, in the journal “iEnergy”.

Ren Ningyu, a postdoctoral researcher, along with doctoral students Tan Liguo and Li Minghao from the 2021 cohort of EEA, Tsinghua University, , are the co-first authors of the paper, with Yi Chenyi as the corresponding author.

Paper link:

https://ieeexplore.ieee.org/document/10478316

News & Events

News & Events