Following the successful opening ceremony and first round of company visits from July 7 to 9 in Naples, the 2025 China-Italy Laboratory of Advanced Manufacturing Summer (CI-LAM) School continued with a series of company visits and course lectures in Bergamo from July 10 to 18. The summer school was jointly organized by the Department of Electrical Engineering at Tsinghua University, the University of Bergamo, and the University of Naples Federico II. Over 50 students and faculty from seven Chinese and Italian universities participated. During the nine days of intensive learning, students from both countries visited six top companies and research institutions, and attended eight cutting-edge academic lectures focused on the integration of advanced manufacturing and artificial intelligence. The event provided a rich exploration of knowledge and practice.

(1) Series of Company and Laboratory Visits

01. Visit to Multinational Electrical Equipment Company Schneider Electric

On the afternoon of July 10 at 2:00 PM, students visited the Schneider Electric campus in Bergamo, Milan. The visit began with presentations from three senior managers of Schneider Electric, who provided a detailed introduction to the company’s core principles: sustainability and green development. Schneider Electric views sustainability as key to addressing global climate crises and resource challenges, as well as a significant business opportunity. Sustainability and green development have been deeply integrated into the company’s DNA and business model. The core idea is that tackling climate change and resource challenges is not just a moral responsibility but also key to future commercial success. Through its rigorous "Sustainability Impact" framework, commitment to net-zero emissions across the entire value chain, decarbonization empowerment through digitalization and electrification, embracing a circular economy, building a responsible supply chain, and continuous transparent reporting, Schneider Electric not only practices green development but also aims to become a key enabler for global enterprises and communities to achieve an efficient and sustainable future.

After the lecture, students split into two groups to visit the company’s exhibition hall showcasing smart switchgear, intelligent data monitoring systems, and smart switchgear production lines in the manufacturing area.

Visit to Schneider Electric

02. Visit to Multinational Advanced Manufacturing Companies Cosberg and Tenaris

On the morning of July 11 at 8:30 AM, students split into two groups and visited Cosberg and Tenaris, both located in Bergamo, Milan.

Cosberg is a leading enterprise focused on the development and production of industrial automation assembly systems and special equipment. The company specializes in the design and manufacture of transfer-type assembly machines, including systems for free conveyors and rotary tables, as well as small-to-medium-sized assembly lines. These systems are applied in fields such as automotive parts (pistons, brake systems, window motors), electromechanical components (safety switches, sockets), and furniture accessories. Cosberg’s core patent technologies, including electromagnetic/piezoelectric resonant bowl feeders and its proprietary COP intelligent control system, enable precise handling of micro parts and high-efficiency assembly (500-5000 units/hour), serving top clients in automotive parts and electromechanical components. Students first attended a lecture on precision processing of parts, followed by a tour of the parts processing production line.

Visit to Cosberg

Tenaris is a global leader in the steel pipe manufacturing industry, with a 20% share of global seamless steel pipe production and 30% of the global export market for oil-specific pipes. The Dalmine plant in Bergamo is Tenaris' operations headquarters in Italy, focusing on producing seamless steel pipes for oil, gas, and industrial automation, with an annual output of about 800,000 tons, supporting European and global energy infrastructure needs. Students first attended a lecture by the technical director on the company’s pipe manufacturing technology, which covered special structures and processes of its pipes. Later, they visited the production line and the production control center for pipes.

Visit to Tenaris

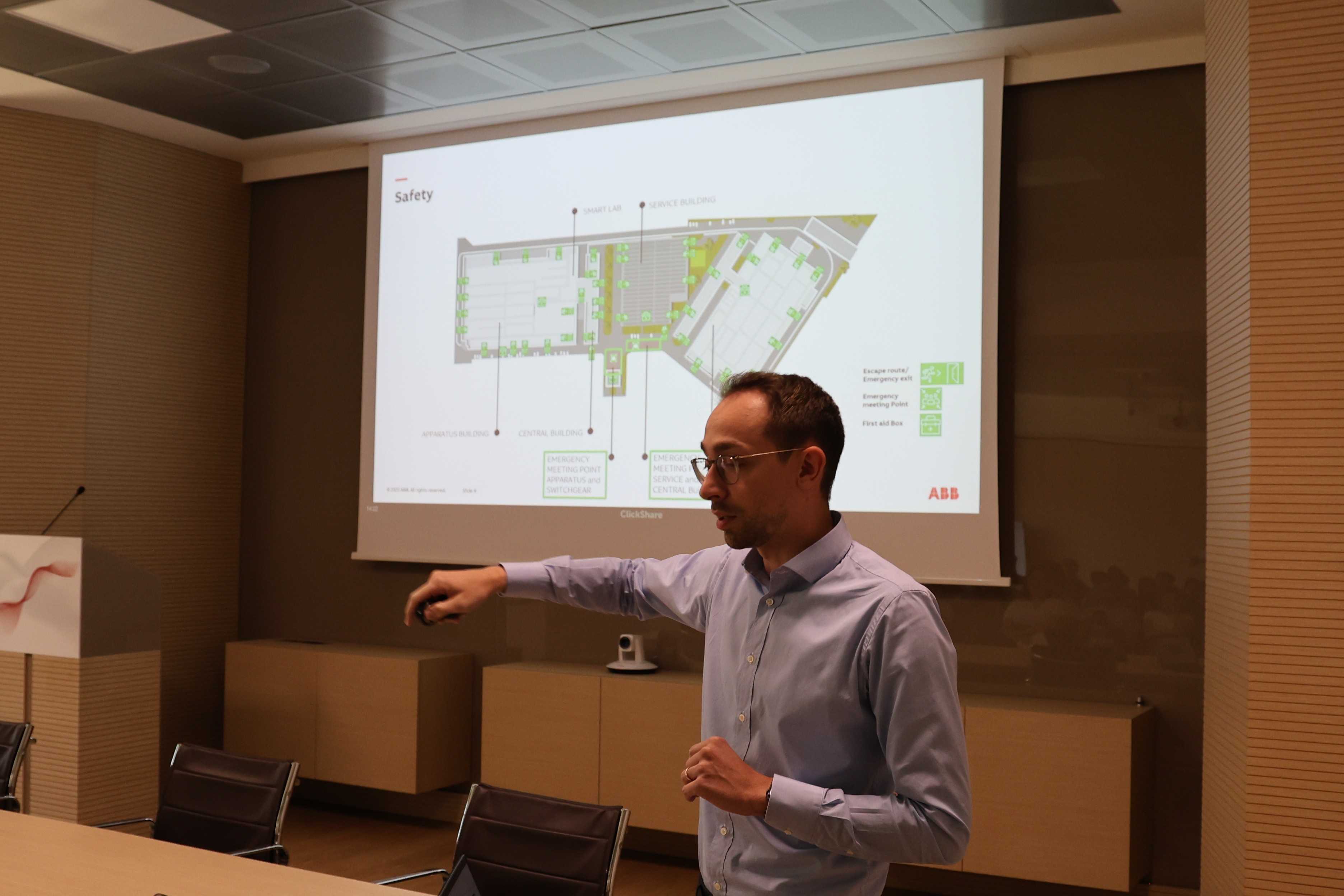

03. Visit to Multinational Electrical Equipment Company ABB

On the afternoon of July 11 at 2:00 PM, students visited the ABB campus in Bergamo, Milan. The visit began with a presentation from ABB managers about the company’s main businesses and manufacturing operations in Italy, covering electric transportation, industrial automation, and sustainable manufacturing. Later, students toured the production workshops for intelligent switchgear and smart charging devices.

Visit to ABB

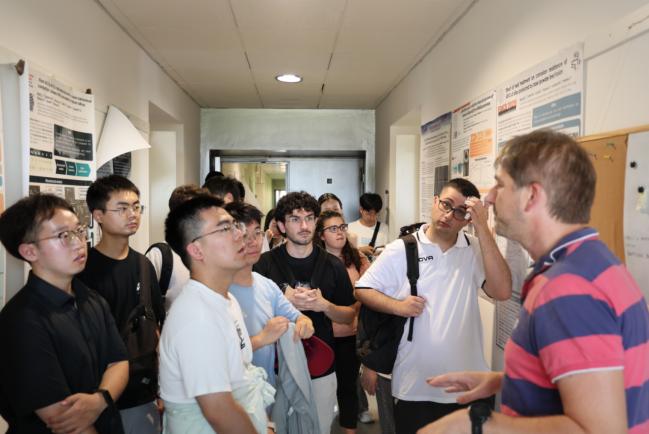

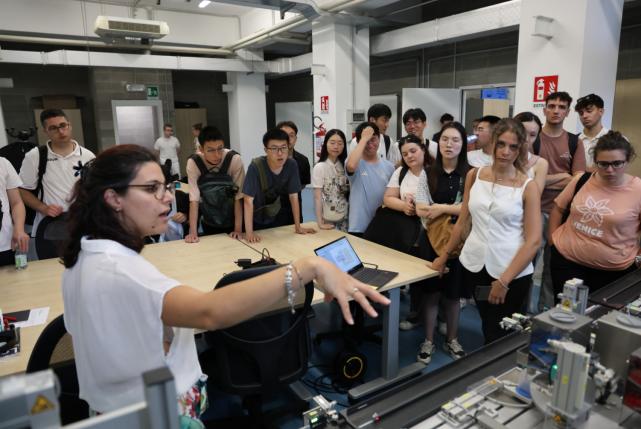

04. Visit to University Laboratory of Bergamo

On the afternoon of July 14 at 3:00 PM, students visited the University of Bergamo’s laboratories. They first visited the materials laboratory, where Professor Sergio Lorenzi introduced the entire process of materials from design to manufacturing and testing, as well as AI-driven material structure and performance design. Students then visited the university’s IC design and application laboratory, which focuses on energy management, sensors, and the design and application of control chips for aerospace. Finally, they visited the comprehensive technology laboratory for image recognition, material auto-classification, and other applications.

Visit to the University of Bergamo Laboratory

05. Visit to the Innovation Incubation Base Kilometro Rosso Innovation District

On the afternoon of July 15 at 3:00 PM, students visited the Kilometro Rosso Innovation District in Bergamo, Milan. After an introduction by the park manager, students learned that Kilometro Rosso is a leading European hub for industry-academia integration, hosting 52 institutions, including Brebmo and i.lab laboratories, forming an industrial ecosystem for smart manufacturing, biomedicine, and advanced materials. The district’s LEED Platinum-certified sustainable buildings feature self-cleaning concrete and smart energy systems, operating on 100% green electricity. Through the China-Italy Innovation Corridor and international technology forums, the park promotes the global export of technology and has reshaped the European innovation model of “technology-ecology-economy” collaboration. Students later visited the park’s materials design and manufacturing and robotics control laboratories, experiencing various novel application scenarios.

Visit to Kilometro Rosso Innovation District

(2) Series of Course Lectures

From July 14 to 17, each morning from 9:00 AM to 12:00 PM, students participated in two lectures on advanced manufacturing and artificial intelligence topics.

The first lecture, titled “Sustainability and Circularity,” was given by Professor Christian Spreafico from the University of Bergamo. He analyzed the core concepts of sustainability and circularity in advanced manufacturing, focusing on green design, smart production, and resource recycling to create a closed-loop system that minimizes resource consumption, waste emissions, and environmental footprint, achieving a win-win situation for both the economy and the environment.

The second lecture, titled “Design and Control of Precision Opto-Mechatronic Systems,” was delivered by Associate Professor Zhang Zhen from Tsinghua University. He focused on the design and control characteristics of precision opto-mechatronic systems, explaining how multi-disciplinary collaboration can build high-precision dynamic systems, using real-time sensor feedback and intelligent algorithms to actively suppress disturbances and achieve closed-loop control for stable imaging/processing/measurement at the micro/nano level.

The third lecture, titled “Edge Intelligent Computing in Energy Harvesting Systems,” was delivered by Professor Qiu Keni from Capital Normal University. She focused on the characteristics of edge intelligent computing in energy harvesting systems, using intelligent resource scheduling and optimization algorithms (such as online control, game theory, and Lyapunov optimization) to maximize edge computing efficiency (task processing rate/energy efficiency) while ensuring service quality (low latency, reliability).

The fourth lecture, titled “Additive Manufacturing (AI, New Materials Development),” was given by Professor Sergio Lorenzi from the University of Bergamo. He explained the applications of AI in materials science, including the optimization of multi-scale manufacturing processes (e.g., molten pool monitoring/topology generation), and the development of high-performance new materials (e.g., gradient alloys/smart composites) to achieve high-precision, customized, high-performance manufacturing of complex components.

The fifth lecture, titled “Green Industrial Internet of Things: Lightweight Backscatter Communication,” was delivered by Associate Professor Zhang Rongrong from Capital Normal University. She discussed how passive devices can achieve ultra-low power (μW level) data modulation and transmission using ambient RF signals (e.g., Wi-Fi/LoRa carriers), by modulating the impedance of scatterers to encode sensor information into reflected waves, overcoming battery limitations and being compatible with existing industrial wireless infrastructure (BLE/ZigBee).

The sixth lecture, titled “Machine Learning for Next-Gen Networks: Trends and Technologies,” was delivered by Professor Stefania Zinno from the University of Naples Federico II. She explained how intelligent technologies such as federated learning (FL), deep reinforcement learning (DRL), and generative AI (GAI) can dynamically optimize network resources (e.g., slice management, task offloading, spectrum allocation), improving energy efficiency and low-latency performance while addressing challenges related to security, scalability, and model convergence in heterogeneous environments.

The seventh lecture, titled “From Industrial Arms to Humanoids: A Journey Through 50 Years of Robotics,” was given by Professor Pierluigi Arpenti from the University of Naples Federico II. He analyzed the evolution of robotics over 50 years, focusing on the intelligent upgrades of the perception-decision-execution loop (from fixed programming to AI autonomous decision-making), combined with bionic structure design and high-precision drive technologies (e.g., harmonic reducers/flexible joints), enabling task adaptability and human-robot collaboration in both structured factories and open environments.

The eighth lecture, titled “AI-Driven Advanced Power Electronics Technology,” was delivered by Professor Sun Kai from Tsinghua University. He reviewed the development of AI technologies and focused on their applications in electrical engineering, including AI-driven power electronics design and simulation, AI-based electrical equipment fault diagnosis and intelligent operation and maintenance, and data-driven power system stability control. He also discussed the future prospects of AI in the electrical field.

Lecture Scene

Through systematic company visits and high-level academic lectures, this CI-LAM Summer School provided a valuable platform for students to understand global trends in advanced manufacturing and the core applications of artificial intelligence technologies. Students not only experienced innovative practices by industrial giants like Schneider Electric, ABB, and Tenaris, but also visited cutting-edge laboratories at institutions such as the University of Bergamo and the Kilometro Rosso Innovation District. The eight lectures covered a wide range of topics, including sustainable green manufacturing, precision systems, robotics, and AI-enabled advanced manufacturing, offering students deep exchanges with leading scholars in the field. The event was rich in content and diverse in perspectives, and students expressed that they gained substantial knowledge in building academic systems, recognizing cutting-edge technologies, and expanding international vision, laying a solid foundation for future academic research or career development.

News & Events

News & Events